Engineering and Product Development

At PRINEMO, we provide end-to-end development services for a diverse range of components used across multiple industries.

Our integrated approach combines expertise in material science, engineering design, and advanced manufacturing processes to create high-performance solutions adapted to specific application needs.

From concept to production, we ensure each component meets rigorous standards for quality, functionality, and sustainability—supporting various industries such as automotive, aerospace and more.

Explore a few examples of part families available in our offer below.

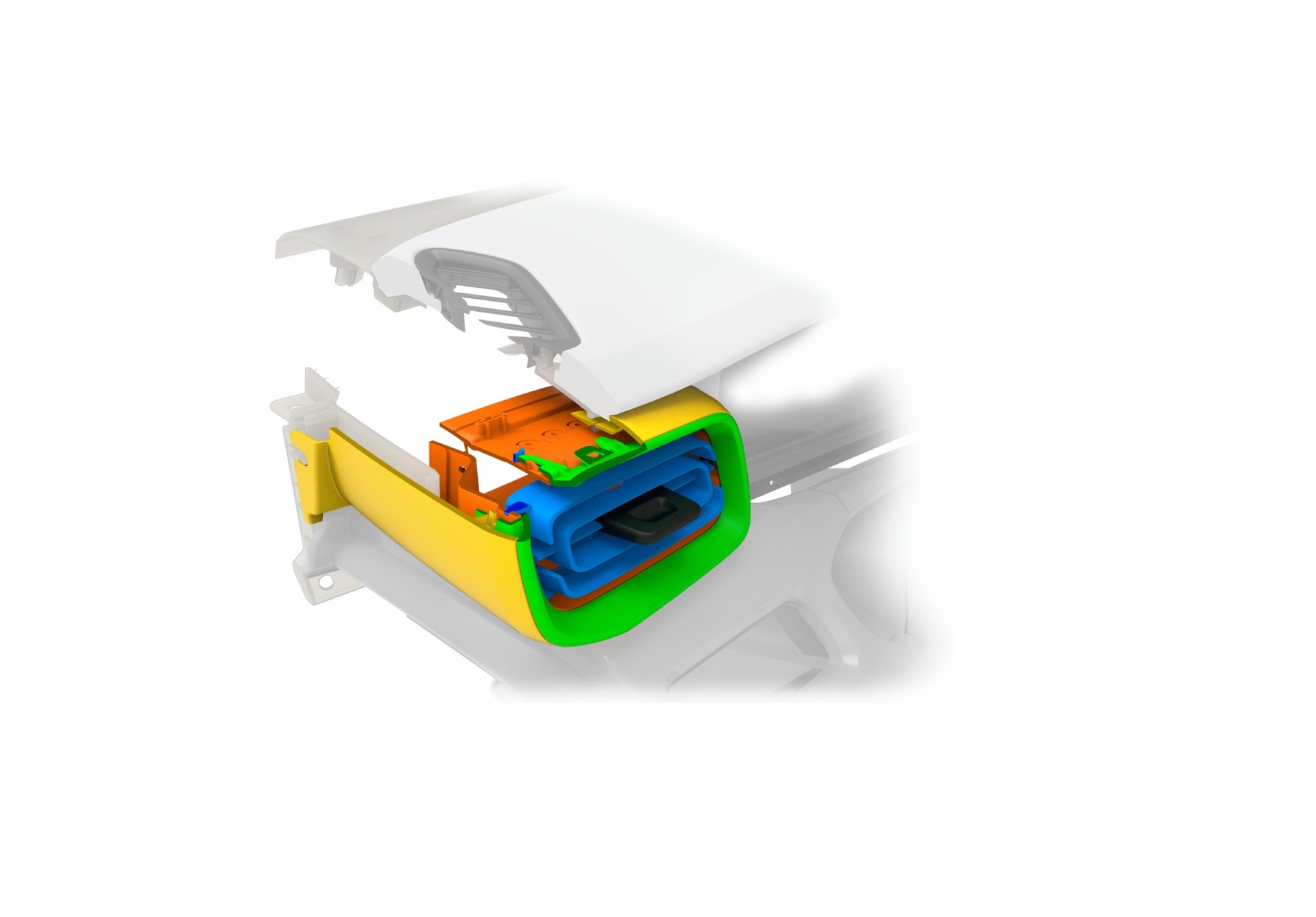

Plastic Parts development

We have extensive experience in the design and development of high-performance plastic components, with deep knowledge of the automotive sector. Our solutions meet the industry’s strict standards for safety, durability, and functionality, while also addressing the demand for lightweight and cost-effective products. Through the companies that make up the Prifer Group, we have the capacity and expertise required for the production and industrialization of plastic injection molds.

Key Features of Our Offer

- 2D/3D Product Design- Creation of 2D technical drawings and 3D models to support all stages of product development, including the integration of technical zones while respecting isostatic design rules.

- Class A Surface Feasibility Ensuring that complex surface definitions meet aesthetic and functional requirements without compromising manufacturability.

- Product Feasibility Analysis Critical definition and analysis of undercuts, moving core directions, main ejection axis, wall thickness studies, and evaluation of potential geometry-related defects in plastic parts, etc.

- Management of surrounding parts Ensuring proper fit and functional performance of all components through effective coordination of interfaces with surrounding elements.

- Process Constraints Identifying Optimizing manufacturability from the early stages of development to reduce defects and improve process efficiency.

- Chain of Dimensions and Process Capability Studies: Anticipating and controlling dimensional variation risks by defining critical dimension chains and performing early capability analysis to ensure serial production.

- Gap and Flush Studies Detailed analysis of mating parts and contact surfaces to guarantee optimal fit (good visible quality), avoid interferences, facilitate assembly, and ensure proper function with adjacent components.

- PPAP – Production Part Approval Process Complete preparation and submission of PPAP documentation in line with automotive industry standards, including control plans, FMEAs, capability studies (Cp, Cpk), dimensional reports, material certificates, functional tests, and initial sample documentation. We ensure compliance with required levels and robust validation of components before serial production begins.

Die-casting components

We provide technical support in the design and manufacturing of metal components and products, using processes such as machining, turning, laser cutting, welding, bending, and more. With extensive experience in sectors such as automotive, aerospace, and industrial manufacturing, we deliver robust, efficient, and cost-effective solutions tailored to meet demanding performance and quality standards.

Key Features of our service:

- Product Engineering - Complete development of metal parts — from concept definition to design validation — with a strong focus on functionality, manufacturability, and the robustness of the final product.

- Product Feasibility Analysis - Evaluation of the technical feasibility of the design based on the manufacturing processes involved (milling, turning, welding, etc.), helping to prevent future production issues.

- Material and Treatment Selection - Recommendation of the most suitable metal materials and the required heat or surface treatments to ensure mechanical strength, protection, and long-term durability.

- Integration with Assembly and Adjacent Components - Analysis of interfaces with surrounding parts, including clearances, fits, and assembly accessibility — ensuring proper integration and functionality of the final assembly.

- Industrialization Support - Effective transition from design to production, with support in defining manufacturing processes, cycle times, equipment, and quality control measures.

Development of metal products

We provide technical support in the design and manufacturing of metal components and products, using processes such as machining, turning, laser cutting, welding, bending, and more. With extensive experience in sectors such as automotive, aerospace, and industrial manufacturing, we deliver robust, efficient, and cost-effective solutions tailored to meet demanding performance and quality standards.

Key Features of our service:

- Product Engineering - Complete development of metal parts — from concept definition to design validation — with a strong focus on functionality, manufacturability, and the robustness of the final product.

- Product Feasibility Analysis - Evaluation of the technical feasibility of the design based on the manufacturing processes involved (milling, turning, welding, etc.), helping to prevent future production issues.

- Material and Treatment Selection - Recommendation of the most suitable metal materials and the required heat or surface treatments to ensure mechanical strength, protection, and long-term durability.

- Integration with Assembly and Adjacent Components - Analysis of interfaces with surrounding parts, including clearances, fits, and assembly accessibility — ensuring proper integration and functionality of the final assembly.

- Industrialization Support - Effective transition from design to production, with support in defining manufacturing processes, cycle times, equipment, and quality control measures.

Sheet metal part development

In our approach to sheet metal part development, we combine technical expertise, industrial experience, and specialized software to transform ideas into manufacturable and efficient solutions.

We provide full support from the conceptual phase to production, with a strong focus on design optimization for processes such as stamping, bending, cutting, and forming.

Key Features of our service:

- Product Engineering - Complete development of sheet metal parts from concept to design validation, with a focus on functionality, manufacturability, and structural feasibility of the final product.

- 2D/3D CAD Development - Creation of 3D models and 2D technical drawings according to international standards, ensuring the clarity and precision required for stamping, bending, and cutting processes.

- Sheet Metal Manufacturing Feasibility Analysis - Detailed evaluation of design feasibility considering stamping limitations, bending behavior, springback, minimum angles, and cutting tolerances, helping prevent production failures.

- Form Simulation and Optimization - Use of simulation tools (when applicable) to predict deformations, wrinkling, cracks, and critical areas, allowing optimization of the part geometry before production.

- Tolerance Definition and Critical Fit Analysis - Functional analysis of dimensions and critical fits required for proper operation and assembly, with special attention to bending zones and interlocking features.

- Material and Thickness Selection - Support in selecting the most suitable materials and thicknesses based on mechanical requirements, geometric constraints, and the need for lightweight, strength, and formability.

- Assembly Compatibility and Interface Management - Analysis of interfaces with other components to ensure proper clearances, ease of assembly, and dimensional compatibility with adjacent parts.

- Industrialization Preparation - Support during the transition from design to mass production, including tooling definition, process layout, cycle times, and quality control criteria.

Soundproofing componentes

At Prinemo, we develop customized acoustic insulation solutions tailored to the specific requirements of each application. Our expertise covers acoustic materials, product engineering, and integration with industrial manufacturing processes.

Our services range from initial design to the industrialization of components that contribute to noise and vibration control across various sectors, including automotive, home appliances, and industrial equipment.

Key Features of our service:

- Product Development - Development of acoustic solutions from the conceptual phase through to design validation, focusing on noise and vibration reduction and improving acoustic comfort in diverse environments and applications.

- 2D/3D CAD Development - Creation of 3D models and 2D technical drawings for acoustic components, adapted to mounting constraints, complex shapes, and integration with existing systems.

- Acoustic Material Selection - Technical selection of the most suitable materials (foams, mats, non-woven fabrics, composites, etc.) based on properties such as sound absorption, insulation, thermal resistance, and flammability.

- Manufacturing Feasibility and Application Studies - Evaluation of the technical feasibility of the design, considering cutting, bonding, thermoforming, and either manual or automated application methods.

- Acoustic Simulation and Validation - Simulation and testing to predict acoustic behavior, optimize material thickness and component positioning, including layout optimization for roll usage or standard material dimensions.

- Integration with Assembly and Adjacent Components - Analysis of interfaces with metal or plastic surfaces, ensuring geometrical compatibility, adhesion, ease of installation, and durability in operation.

- Preparation for Mass Production - Support for industrialization, including definition of manufacturing processes, tolerances, and quality control for stable and efficient production. Assistance in defining peripheral systems to ensure proper placement of acoustic parts on components.

OUR SOFTWARES